A C-Chart Is Based On The . These are simply ± 1 sigma, ± 2 sigma and ± 3 sigma from the center line. Once you’ve chosen a starter template, click the data tab in the left sidebar to find your chart type.

How To Implement A Control Chart For Six Sigma - Dummies from www.dummies.com

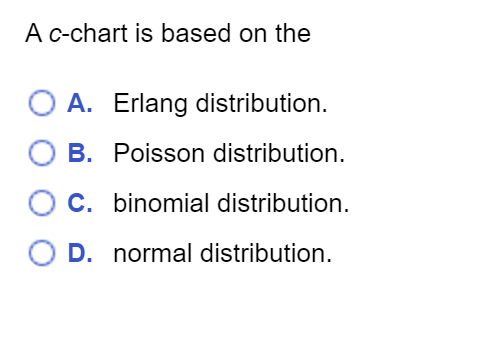

Variables data can, theoretically, be measured to any precision you like. C charts are used to monitor the number of nonconformities on a unit of a process based on units taken from the process at given times (hours, shifts, days, weeks, months, etc.). Selection of control chart the control chart is a graph used to study how process changes over time.

How To Implement A Control Chart For Six Sigma - Dummies

Start a new project and choose a template based on how you want to showcase your data. The lesson will include practice creating the chart. Points will be deducted if you print out full data. A control chart always has a central line for average, an upper line for upper control limit, and lower line for the lower control limit.

Source: www.spcforexcel.com

When you cannot count “not a defect.” data type is discrete but each count has an equal opportunity of coming up. To establish the control limits for a process. Plot of the number of defects in items. Excel offers the following major chart types −. Once you’ve chosen a starter template, click the data tab in the left sidebar to.

Source: www.dummies.com

C charts are used to monitor the number of nonconformities on a unit of a process based on units taken from the process at given times (hours, shifts, days, weeks, months, etc.). Start a new project and choose a template based on how you want to showcase your data. The formula for sigma varies depending on the type of data.

Source: sixsigmastudyguide.com

The center line equals either the average or median of your data. When you cannot count “not a defect.” data type is discrete but each count has an equal opportunity of coming up. Start a new project and choose a template based on how you want to showcase your data. Find all the roots of a quadratic equation ax 2.

Source: www.semanticscholar.org

Examples of variables data include time, length, width, density, dollars, and height. Both the c and u control charts are used to. Plot of the number of defects in items. The average number of defects per sample is 36.68. Start a new project and choose a template based on how you want to showcase your data.

Source: en.wikipedia.org

Once you’ve chosen a starter template, click the data tab in the left sidebar to find your chart type. The lesson describes how to create this control chart in both microsoft excel and using minitab. Typically, an init ial series of units is used to estimate the average number of nonconformities of a process. Nonconformities are defects or occurrences found.

Source: www.spcforexcel.com

Use c chart to monitor the number of defects where each item can have multiple defects. Diabetes control and complications trial or dcct, new england journal. Use this control chart to monitor process stability over time so that you can identify and correct instabilities in a process. You should use a c chart only when your subgroups are the same.

Source: sixsigmastudyguide.com

The engineer should identify and correct any factors that. For the control chart, the size Variables data are taken from a continuum and are often referred to as continuous. The c chart (plots counts) is the simplest of the attribute data control charts. Excel offers the following major chart types −.

Source: www.researchgate.net

Understanding c and u control charts. Flowchart fo display the fibonacci series. Use tests 1 and 2 when you first establish the control limits based on your data. Points will be deducted if you print out full data. Which of the following statements is false regarding control charts?

Source: en.wikipedia.org

Dcct a1c conversion formula seems to work best in people with high blood sugars. Variables data are taken from a continuum and are often referred to as continuous. A control chart always has a central line for average, an upper line for upper control limit, and lower line for the lower control limit. If you don't have data based on.

Source: www.researchgate.net

This lesson explains how the data is recorded and interpreted on the chart. To establish the control limits for a process. Step 7 − give a meaningful title to the chart by editing chart title. These are simply ± 1 sigma, ± 2 sigma and ± 3 sigma from the center line. Which of the following statements is false regarding.

Source: www.chegg.com

Based on the type of data, you can create a chart. Excel provides you different types of charts that suit your purpose. For the control chart, the size Which of the following statements is false regarding control charts? Flowchart fo display the fibonacci series.

Source: www.chegg.com

Based on the type of data, you can create a chart. Variables data are taken from a continuum and are often referred to as continuous. These are simply ± 1 sigma, ± 2 sigma and ± 3 sigma from the center line. A1c level chart in this article shows the relationship between a1c and its average blood sugar equivalent, based.

Source:

C chart is one of the quality control charts used to track the number of defects in a product of constant size total opportunity population is large compared to # defects. Charts must have titles and labels. The centerline of the c chart (c̅) is the total number of defects divided by the number of samples. The lesson will include.

Source: www.qimacros.com

For the control chart, the size Excel provides you different types of charts that suit your purpose. How to use c charts: Variables data can, theoretically, be measured to any precision you like. Prepositions of time at in on;

Source: slidetodoc.com

A control chart always has a central line for average, an upper line for upper control limit, and lower line for the lower control limit. Third, calculate the sigma lines. Use c chart to monitor the number of defects where each item can have multiple defects. The engineer should identify and correct any factors that. Prepositions of time at in.

Source: towardsdatascience.com

Click ok in each dialog box. • these are graphs that visually show if a sample is within statistical control limits. About join forums grammar vocab pronunciation. Variables data are taken from a continuum and are often referred to as continuous. You can choose a table chart, a line chart, a radar chart or any other chart type you need.

Source: www.brighthubpm.com

Nonconformities are defects or occurrences found in the sampled subgroup. Excel provides you different types of charts that suit your purpose. The c chart is for the number of defects in an item. Explore answers and all related questions. Based on the type of data, you can create a chart.

Source: cpr-tech.com

For the control chart, the size You should use a c chart only when your subgroups are the same size. Use c chart to monitor the number of defects where each item can have multiple defects. Use tests 1 and 2 when you first establish the control limits based on your data. The c chart is for the number of.

Source: www.spcforexcel.com

The lesson describes how to create this control chart in both microsoft excel and using minitab. Third, calculate the sigma lines. Only present control charts and mini tables. The estimated value is then used to produce control limits for the number of nonconformities. Find all the roots of a quadratic equation ax 2 +bx+c=0.

Source: www.pqsystems.com

Dcct a1c conversion formula seems to work best in people with high blood sugars. Excel provides you different types of charts that suit your purpose. Flowchart to find roots of a quadratic equation. Numbers in mini tables must show 3. Use tests 1 and 2 when you first establish the control limits based on your data.