Forming Tap Drill Chart . To establish tap drill sizes for inch size roll forming taps tap drill size = basic tap o.d. Tap size cut tap drill roll tap drill minor θ major θ;

Finding The Right Drill Size For Tapping | Blog | Resources from shopmetaltech.com

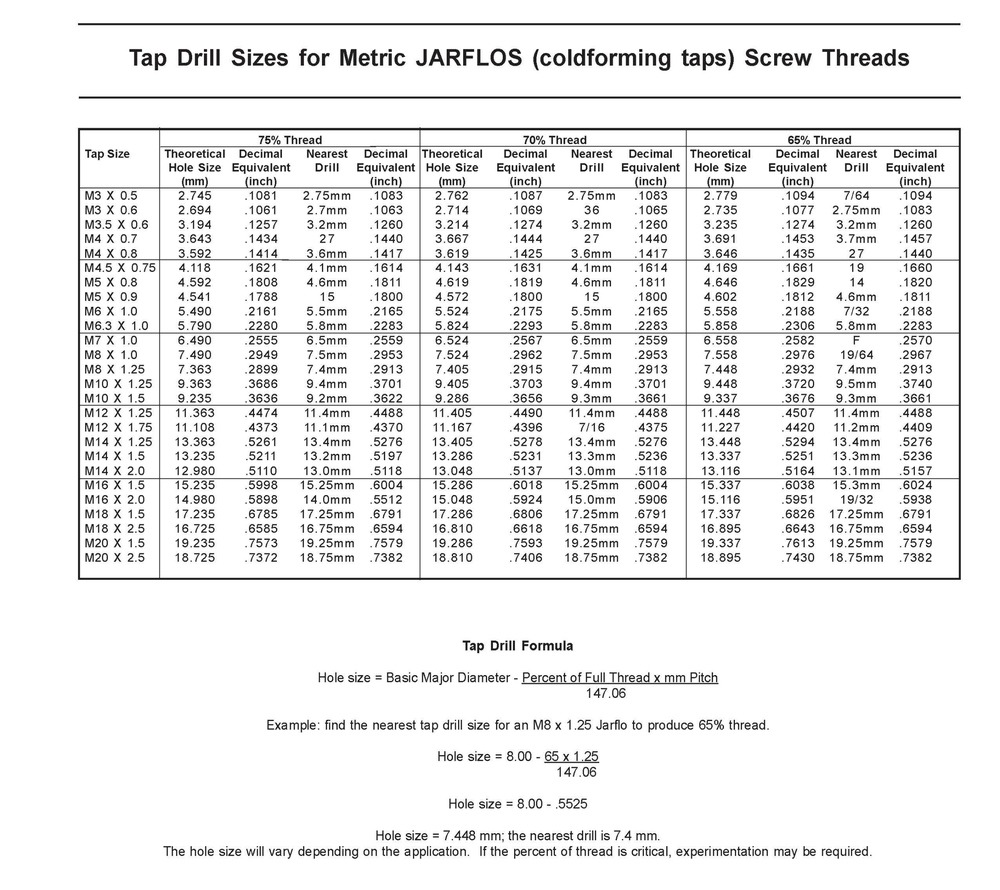

147.06 (example m8 x 1.25 tap with 65% thread) = 8 — application forming taps cold form. Tap limit is determined with 80% of the tolerance at the internal thread as an aim. Pitch (mm) drill size (mm) tap dia.

Finding The Right Drill Size For Tapping | Blog | Resources

Cutting taps 68% to 70% recommended calculate. (mm) — (% of thread desired x mm pitch) 147.06 (example m8 x 1.25 tap with 65% thread) = 8 — (65 x 1.25) = 7.45mm dia. Drill & tap chart created date: Rf 100 90° end mills:

Source: www.kodiakcuttingtools.com

(mm) — (% of thread desired x mm pitch) 147.06 (example m8 x 1.25 tap with 65% thread) = 8 — (65 x 1.25) = 7.45mm dia. Drill the hole of the right length. After that, tighten the tap by positioning the square of the tap on top of the holder. To establish tap drill sizes for inch size roll.

Source: www.osgtool.com

A tap drill chart is key in matching pairs of female and male thread that tightly secure together. 88 rows or they can consult a tap drill chart like those found in the next section. Printable chart downloads at the bottom of the page. Determine hole diameter by tapping test. Often it is the corresponding dies and taps that you.

Source: www.mscdirect.com

Tapping drill size for thread forming. Thread forming taps move the material to form the threads. We encourage all to build and buy american made. 88 rows or they can consult a tap drill chart like those found in the next section. Fractional sizes are listed in inches, while metric sizes are listed in millimeters following the letter m.

Source: www.jarviscuttingtools.com

We are proudly american made for 119+ years. To establish tap drill sizes for inch size roll forming taps tap drill size = basic tap o.d. Often it is the corresponding dies and taps that you see together when buying either ones. Cutting taps 68% to 70% recommended calculate. 54 rows download tap drill pdf charts.

Source: shopmetaltech.com

Rf 100 90° end mills: Buy american for a better america! Fractional sizes are listed in inches, while metric sizes are listed in millimeters following the letter m. The decimal equivalents of the diameters are shown in both english and metric units. Often it is the corresponding dies and taps that you see together when buying either ones.

Source: www.pdffiller.com

The decimal equivalents of the diameters are shown in both english and metric units. Tap drill clearance drill 19.00 5.25. Drill & tap chart created date: 88 rows or they can consult a tap drill chart like those found in the next section. Cutting taps 68% to 70% recommended calculate.

Source: www.jarviscuttingtools.com

Often it is the corresponding dies and taps that you see together when buying either ones. Depending upon the material and thickness being used, you may. Printable chart downloads at the bottom of the page. Hole sizes for metric threads and tap limit of taflet. Thread forming taps move the material to form the threads.

Source: www.jarviscuttingtools.com

Rf 100 90° end mills: The dimensions in this table are for reference only. Rf 100 speed end mills: Tap size cut tap drill roll tap drill minor θ major θ; Calculate major diameter for tap drill size.

Source: www.jarviscuttingtools.com

A drill and tap chart is what specifies the right size of drill bit that one can use to create the correct sized opening that would complement tap dimensions. Cutting taps 68% to 70% recommended calculate. We support the made in the usa movement. Tap drill clearance drill 19.00 5.25. Buy american for a better america!

Source: www.guhring.com

54 rows download tap drill pdf charts. The dimensions in this table are for reference only. Pitch (mm) drill size (mm) tap dia. Rf 100 speed end mills: Pitch (mm) drill size (mm) tap size tpi drill size (mm) m 1 0.25 0.90 m 10 1.25 9.51 4 40 2.60 m 1.1 0.25 1.00 m 10 1.50 9.41 4 48.

Source: www.jarviscuttingtools.com

Look at the tap and drill chart to determine the proper size, and then begin drilling. A tap drill chart is key in matching pairs of female and male thread that tightly secure together. To establish tap drill sizes for inch size roll forming taps tap drill size = basic tap o.d. Pitch (mm) drill size (mm) tap size tpi.

Source: www.pinterest.com

Unified national form (60º) 1/4 32 5.6 5/16 32 7.2 3/8 32 8.8 1/2 28 11.8 5/8 24 14.75 3/4 20 18 1 20 24.2 bsw british standard whitworth (55º) tap size tpi tapping drill mm 1/16* 60 1.2 3/32* 48 1.85 1/8 40 2.55 5/32* 32 3.2 3/16 24 3.7 7/32* 24 4.5 1/4 20 5.1 5/16 18 6.5.

Source: mefexport.com

Tap drill clearance drill 19.00 5.25. Tap size cut tap drill roll tap drill minor θ major θ; Drill the hole of the right length. Look at the tap and drill chart to determine the proper size, and then begin drilling. Printable chart downloads at the bottom of the page.

Source: www.pinterest.ca

Determine hole diameter by tapping test. Look at the tap and drill chart to determine the proper size, and then begin drilling. However, the particular drill chart is. Tap limit is determined with 80% of the tolerance at the internal thread as an aim. Drill size for thread forming @ 57.5% thread metric threads metric threads unc / unf threads.

Source: www.pinterest.com

Rf 100 90° end mills: 147.06 (example m8 x 1.25 tap with 65% thread) = 8 — application forming taps cold form. 88 rows or they can consult a tap drill chart like those found in the next section. Printable chart downloads at the bottom of the page. Thread forming taps move the material to form the threads.

Source: www.guhring.com

A tap drill chart is key in matching pairs of female and male thread that tightly secure together. (mm) — (% of thread desired x mm pitch) 147.06 (example m8 x 1.25 tap with 65% thread) = 8 — (65 x 1.25) = 7.45mm dia. Determine hole diameter by tapping test. Hole sizes for metric threads and tap limit of.

Source: pdf4pro.com

Metric tap & clearance drill sizes 3/4. Cutting taps 68% to 70% recommended calculate. Determine hole diameter by tapping test. Rf 100 90° end mills: The dimensions in this table are for reference only.

Source: www.stgmachine.com

Drill & tap chart created date: 147.06 to establish tap drill sizes for inch size roll forming taps tap drill size = basic tap o.d. Unified national form (60º) 1/4 32 5.6 5/16 32 7.2 3/8 32 8.8 1/2 28 11.8 5/8 24 14.75 3/4 20 18 1 20 24.2 bsw british standard whitworth (55º) tap size tpi tapping drill.

Source: templatelab.com

50% thread for steel, stainless & iron 75% thread for aluminum, brass & plastics. Printable chart downloads at the bottom of the page. Rf 100 speed end mills: Pitch (mm) drill size (mm) tap dia. % enter desired % or leave blank if you do not know.

Source: westportcorp.com

Download tap drill chart for stainless steel, iron,. Tap drill clearance drill 19.00 5.25. Determine hole diameter by tapping test. Pitch (mm) drill size (mm) tap size tpi drill size (mm) m 1 0.25 0.90 m 10 1.25 9.51 4 40 2.60 m 1.1 0.25 1.00 m 10 1.50 9.41 4 48 2.64 m 1.2 0.25 1.10 m 11 0.75.